Varnish formation in hydraulic systems can have far-reaching consequences if left untreated. Acting much like cholesterol in the human body, varnish clogs valves, sticks stubbornly to metal surfaces, restricts oil flow and disrupts pressure controls. Once it starts accumulating, it can restrict fluid movement, interfere with proper lubrication and cause wear and tear on components, shortening the life of your hydraulic equipment.

The good news? With the right maintenance strategies, such as regular oil analysis, proper filtration and the use of varnish-resistant lubricants, you can minimize varnish formation and keep your hydraulic systems running smoothly.

What Is Varnish?

Varnish is a thin, hard, sticky film composed of degraded lubricant byproducts. It forms when hydraulic oil oxidizes or thermally degrades, producing insoluble molecules that eventually settle onto component surfaces such as:

• Servo and proportional valves

• Control valves and spools

• Reservoir walls

• Filter media

• Pump and motor internals

Over time, these deposits build up, restrict fluid flow and interfere with tight clearances critical to system responsiveness.

Causes and Effects of Varnish Formation

Varnish buildup in hydraulic systems is often driven by several key factors, particularly in systems operating under high pressure and with tight tolerances:

1. Lubricant Oxidation

Elevated temperatures, overused oil and trapped air can cause your hydraulic oil to break down faster. When this happens, the oil creates harmful byproducts like acids and carbon deposits. Over time, these can form sticky varnish that clogs your system, reduces efficiency and increases maintenance needs. This results in more downtime and potential damage to your hydraulic equipment if not addressed.

2. Thermal Hot Spots

Varnish in hydraulic systems is often caused by thermal hot spots, like valve lands or pump bearings, which generate intense heat. This heat leads to oil degradation through processes like micro-dieseling or thermal cracking, forming carbon-based solids that build up as varnish on components, causing sticking valves, reduced efficiency, increased wear and unexpected failures.

Over time, this can lead to increased maintenance expenses, unexpected downtime and a shorter lifespan for your equipment. To avoid these challenges, prioritize monitoring oil conditions, using high-quality lubricants and implementing efficient filtration systems.

3. Electrostatic Discharge (ESD)

Low-conductivity fluids moving at high speeds through the oil filter can generate static charges through friction in hydraulic systems. These charges can cause electrostatic discharges, leading to microscopic sparking — breaking down the oil and creating varnish.

For industrial plants, varnish can clog filters, reduce efficiency and damage key parts like valves and pumps, leading to higher maintenance costs, unplanned downtime and shorter equipment life. Preventing varnish requires addressing electrostatic discharge and monitoring fluid quality to maintain reliable system performance.

4. Poor Filtration and Contamination

Varnish formation in hydraulic systems is often caused by ineffective filtration, poor maintenance and the recirculation of contaminants such as debris, water and degraded oil. These impurities lead to the build-up of deposits over time.

The result? Clogged valves, restricted fluid flow and impaired heat transfer, causing downtime and higher maintenance costs. Proper filtration and regular system upkeep are essential to ensure reliable operation.

The Effects of Varnish on Hydraulic Systems?

Varnish might seem like an aesthetic issue — until it starts interfering with system performance. Key affects include:

• Sticky Valves: Restricts spool movement, causing a sluggish or erratic response.

• Pressure Spikes: Reduced clearances in control valves cause pressure instability.

• Pump Wear: Deposits reduce lubrication efficiency and increase friction.

• Filter Blinding: Varnish sloughs off into fine particles that block filters prematurely.

How to Detect Varnish Before It Causes Failure

Early detection is key to minimizing damage. Tools and techniques include:

• Membrane Patch Colorimetry (MPC): A lab test that quantifies varnish potential using a precise color scale. By identifying the presence of varnish-forming contaminants early, MPC helps prevent the buildup of deposits that can lead to increased friction, reduced efficiency and potential damage to hydraulic system components.

• FTIR and RULER Tests: FTIR (Fourier Transform Infrared Spectroscopy) analyzes the chemical composition of the oil, identifying signs of oxidation, contamination or additive depletion. RULER (Remaining Useful Life Evaluation Routine) tests specifically measure the remaining antioxidant levels in the oil, which are critical for preventing oxidation and prolonging the oil’s life. Together, these tests help detect early signs of oil degradation and chemical changes.

• Visual Inspections: Regular visual inspections, like checking for sticky or darkened components inside valves and actuators, can help identify early signs of wear, contamination or damage in hydraulic systems. Catching these issues early allows for timely maintenance or repairs, reducing the risk of system failures and preventing costly damage.

• Valve Response Monitoring: Erratic motion or lag times may indicate surface deposits. Identifying and addressing these issues promptly can help reduce damage to hydraulic systems by preventing excessive wear and ensuring smooth operation.

If your oil looks clean, but your valves are sticking, varnish is likely to blame.

How to Prevent and Eliminate Varnish

✔ Use Oxidation-Resistant Lubricants

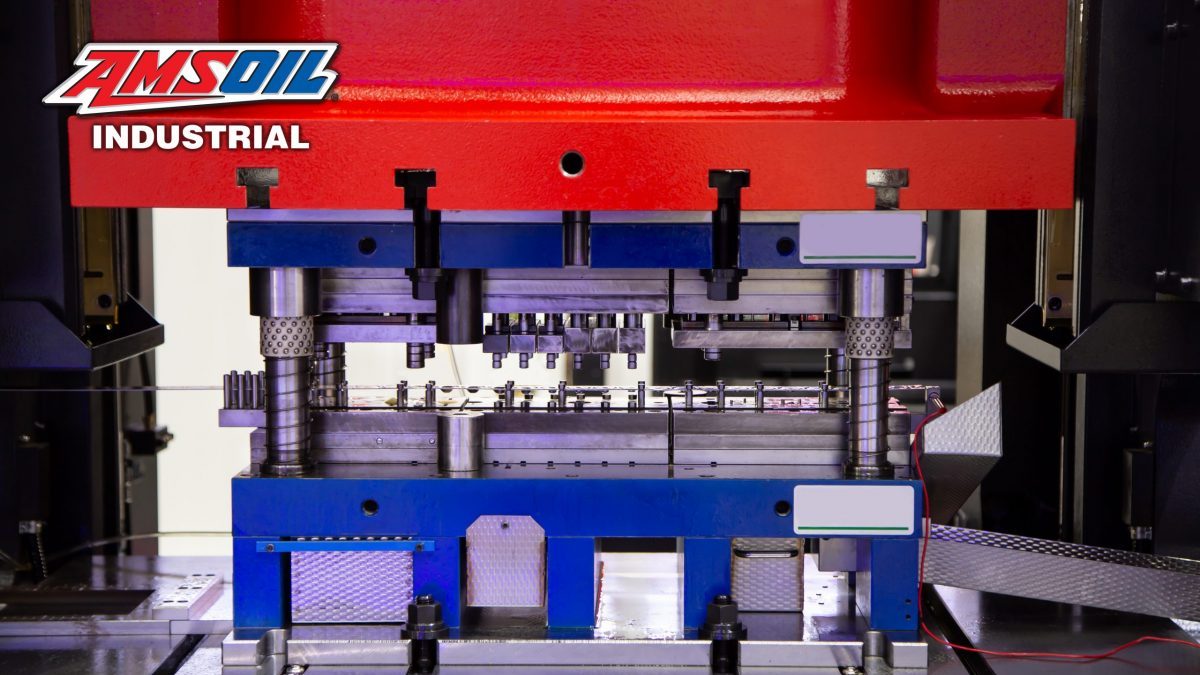

Choose high-performance fluids formulated with premium synthetic base oils and strong antioxidant packages. AMSOIL Industrial hydraulic fluids are engineered to resist varnish formation and maintain performance under severe operating conditions.

✔ Maintain Optimal Operating Temperatures

Keep oil temperatures within the manufacturer’s recommended range to slow oxidation. Address hot spots or overheating conditions immediately.

✔ Control Entrained Air and Water Contamination

Reduce fluid air entrainment to better regulate oil temperature and maintain water contamination levels below 200 ppm. This minimizes additive depletion and helps prevent varnish formation.

✔ Upgrade Your Filtration

Install high-efficiency varnish mitigation filters to effectively eliminate insoluble varnish precursors. For critical systems, consider advanced solutions, such as electrostatic or depth filtration, to ensure optimal performance.

✔ Implement Fluid Monitoring

Routine oil analysis, including MPC and antioxidant depletion testing, can help you intervene before varnish becomes a problem.

Prevent Varnish from Compromising System Reliability

Varnish is one of the most common and preventable causes of hydraulic system failure. With a proactive approach that includes high-performance lubricants, varnish mitigation filters, condition monitoring and technical support, you can preserve equipment reliability, avoid costly downtime and extend fluid life.

Need help diagnosing or preventing varnish?

Talk to an AMSOIL Industrial Application Engineer today.