Plant managers are tasked with reducing operations and maintenance costs by keeping manufacturing equipment operating continuously without interruption. However, heavy equipment use increases overall operational costs, so owners and operators are constantly seeking ways to reduce total cost of ownership by increasing equipment reliability and reducing energy consumption. What if there was a simple solution to both problems?

Multigrade Oil Efficiency Benefits

Hydraulic oil transmits power, so the choice of lubricant directly impacts operational efficiency. Monograde mineral oils flow less efficiently when cold, leading to increased power demand from hydraulic pumps and motors. Monograde oil also gets thinner at operating temperatures, which can lead to pump fluid bypass that negatively affects equipment efficiency. Due to their narrow temperature range, monograde oils may also require seasonal changeouts due to fluctuating operating temperatures.

Multigrade hydraulic oils with a high viscosity index (VI) maintain optimal viscosity within a hydraulic system over a wider temperature range to improve the equipment’s overall operational efficiency. Hydraulic pumps and motors operate more efficiently when the oil viscosity stays within the manufacturer’s recommended range, contributing to reduced energy consumption. The higher viscosity index of multigrade oil supports a much larger range of operating temperature, which improves the efficiency of equipment operated outdoors and can help eliminate seasonal oil changes.

The energy savings experienced when switching to multigrade oil will vary based on the specific hydraulic system, application and operating temperatures. Proper oil and system maintenance are required to maximize these benefits.

Multigrade Oil Reliability Benefits

Hydraulic valve, pump and motor reliability directly affect overall system reliability. An oil’s ability to flow is directly affected by its viscosity, which must remain balanced under a wide range of conditions for optimal reliability. For example, multigrade oils resist thickening better than monograde oils at low temperatures, minimizing the possibility of pump cavitation and pump failure. Likewise, multigrade oils resist thinning better than monograde oils at high temperatures, reducing internal pump bypass, which increases efficiency with additional potential to improve production turns.

When monograde oil gets too cold it can cause cavitation and pump failure. Monograde oils also oxidize faster at elevated temperatures, resulting in varnish, sludge and deposits that reduce hydraulic power, responsiveness and oil and component life.

Multigrade oils maintain viscosity over a wide temperature range, minimizing friction to keep hydraulic systems running cooler. High-quality synthetic base oils with anti-varnish additives also minimize varnish potential to help prevent valve failures and increase the overall reliability of hydraulic systems.

Getting Started

AMSOIL Industrial HELIOS-VR hydraulic oil is engineered with high-quality synthetic base oils and unique anti-wear additives to improve performance and extend valve and pump life in high-pressure hydraulic systems. Its high viscosity index and excellent shear stability provide excellent operating efficiency and superior oil life at extreme temperatures and in severe-service operating conditions, eliminating the need for frequent oil changes and increasing equipment uptime.

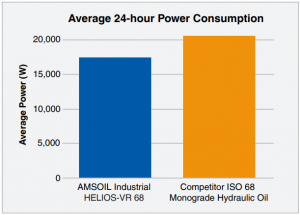

Download the case study to find out how an injection molding plant reduced power consumption by more than 13% with HELIOS-VR, leading to an estimated $27,000 annual energy cost savings. HELIOS-VR also helped the company increase their hydraulic equipment uptime and reduce operations and maintenance costs. Download the HELIOS-VR Report.

Consult an AMSOIL Industrial Application Engineer to identify the best solutions for your specific applications.