Best practices for maximizing uptime and minimizing operations and maintenance costs differ based on the type of equipment and operating environment. AMSOIL Industrial lubrication and application experts provide professional services that can help improve your operational efficiency by extending equipment life and reducing expensive unscheduled downtime.

Lubrication Program Management

As a preventive maintenance tool, a properly implemented lubricant management program can detect specific contaminants and component wear before problems develop to help maximize uptime and extend oil and equipment life.

Drain Intervals

Some oils are engineered to last longer than others, so operations and maintenance costs can be dramatically reduced by choosing the right lubricants. In certain applications adding fresh oil may be all that is needed to extend oil drain intervals.

Equipment Life

Maintaining oil filtration to optimize system cleanliness ensures your equipment will operate efficiently and last a long time. Depending on the application, even a small change in oil cleanliness can significantly reduce downtime, repair and replacement costs.

Lubricant Analysis

AMSOIL Industrial testing laboratories are staffed by expert lubricant analysts who provide timely, accurate and easy-to-understand data that helps you maximize the performance and life of your lubricants and protect your valuable equipment.

High-Quality Testing

To ensure accurate results, lubricants are subjected to advanced testing exceeding the most stringent international standards at ISO 9001 and ISO 17025 A2LA accredited laboratories.

Innovative Technology

Improving the accuracy and consistency of your data will take your lubrication management program to the next level. AMSOIL Industrial Sofia® reporting software quickly delivers your results online so you can make critical decisions more efficiently and effectively.

Lubricant Management

Tracking every fill and top-off event ensures that you always have the right products available when you need them. Our remote inventory management solutions are designed to automatically track oil dispensing events across all of your equipment.

Remote Oil-Condition Monitoring

Actively monitoring changes and trends in lubricant impedance, temperature and viscosity allows you to take proactive measures that reduce the risk of equipment failure. Our remote oil-condition monitoring solutions enhance your maintenance program by making real-time oil quality analysis simple.

AMSOIL Industrial offers an internet-connected inventory-management system that dispenses high-cleanliness lubricants and can automatically track oil dispensing events on multiple pieces of equipment.

Reservoir Management

Maintaining oil quality by preventing cross-contamination and moisture ingress can be as simple as correctly identifying and labeling equipment and implementing cost-effective reservoir management solutions.

For metalworking fluids, oil skimmers continuously remove tramp oil, chips and fines for longer lasting fluid. Skimmers also reduce fungal and bacterial growth for a healthier work environment.

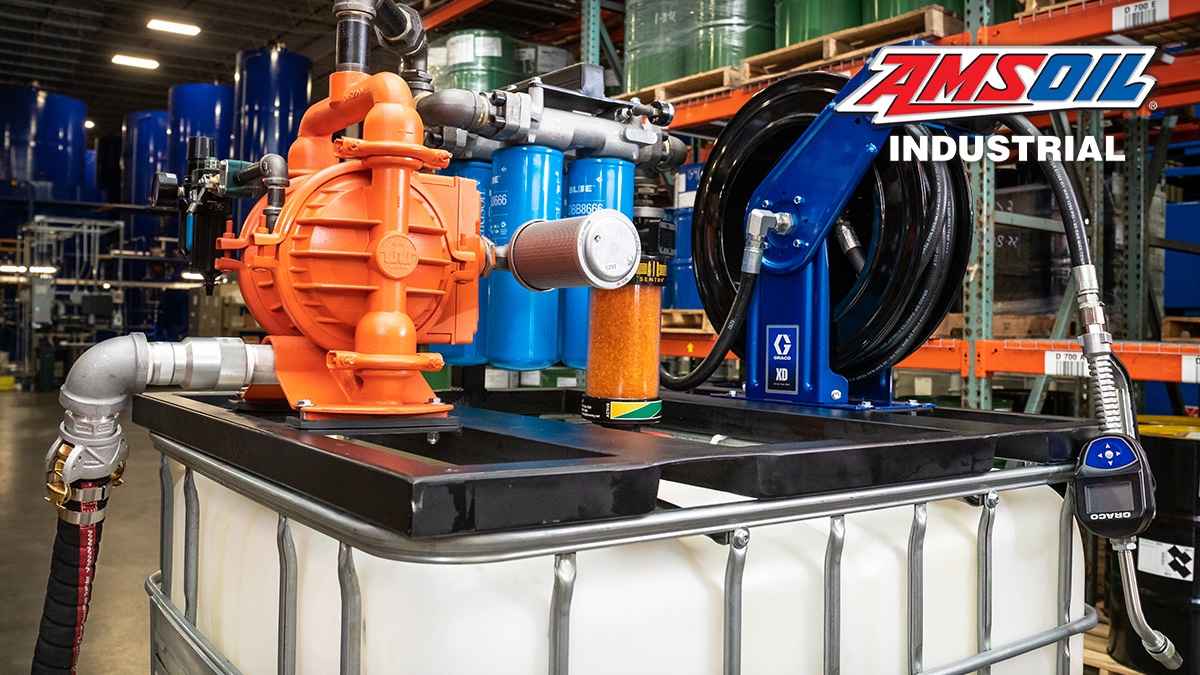

Pumps and Transfer Carts

Our easy-to-use pumps and transfer carts filter oil from drums or totes before it goes in your equipment to simplify lubricant installation, helping you maintain the ISO cleanliness grade and decreasing the risk of cross-contamination.

On-Site Engineering Support

Operational excellence is achieved by identifying and implementing efficient solutions to complex problems. AMSOIL Application Engineers provide custom solutions tailored to your specific equipment and operational objectives backed by decades of experience improving operational efficiency in a wide variety of industries. We leverage our expertise to help you uncover unexpected problems before they spiral out of control and provide innovative ideas to improve uptime, boost production and save money.

Our team can survey your operation to identify any equipment problems and provide recommendations suited to your unique goals. They will help you clarify product applications, establish correct maintenance intervals, consolidate products and identify other opportunities to improve operational efficiency.