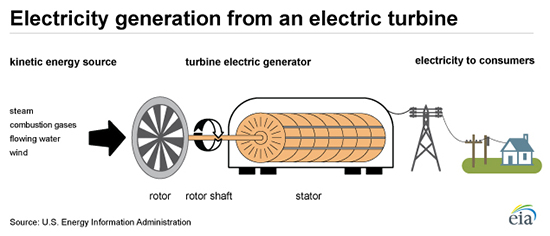

Powered by steam, combustion gases, flowing water or wind, industrial turbines generate most of the electricity used worldwide. Consequently, keeping them running strongly and efficiently is of paramount importance to power plants that rely on them to drive generators. Failure to convert mechanical energy to electrical energy can result in costly downtime and lead to potential safety hazards.

According to the U.S. Energy Information Administration (EIA), “Steam turbines are used to generate most of the world’s electricity, and they accounted for about 42% of U.S. electricity generation in 2022.”

Using the right lubricant, combined with regularly scheduled maintenance and monitoring, can protect industrial turbines from environmental conditions and operational stress — delivering a reliable and steady supply of electricity to consumers. A malfunctioning turbine results in lost energy production. Therefore, it is critical to understand how turbine and generator components work; more so, how they can work better and last long when a proper lubricant is used.

Turbine Components: How They Work

Turbines convert kinetic energy to mechanical energy, and they typically contain some of the following critical components — each of which requires specialized lubricants or regularly scheduled maintenance to ensure uninterrupted output and optimal performance for your specific machine:

Bearings: Support the turbine rotor shaft, ensuring it’s precisely aligned while rotating with minimal friction. Inadequate lubrication of bearings allows for surfaces to come in contact while moving, which can lead to overheating, rust, corrosion and premature wear. On the other hand, excessive greasing can result in wasted lubricant, increased operating temperatures and seal degradation.

Blades: Pressurized steam, gas or water passes by the turbine blades, causing them to rotate and turn the rotor connected to the rotor shaft inside the generator. Improper lubrication or lack thereof will expose components to extreme heat, oxidation and friction, resulting in premature wear.

Seals: A faulty seal can reduce overall efficiency, loss of pressure and lead to equipment failure. Using the wrong lubricant or grease can result in seal degradation over time, making them ineffective. Seals should be checked regularly.

Control valves: Made up of several moving mechanisms, control valves do exactly what the name implies — they control the flow of fluid, gases or steam within turbines. Keeping these key components lubricated ensures pressure is regulated, optimizing the turbine’s performance. When components fail, valves will not function properly.

Generator Components: How They Work

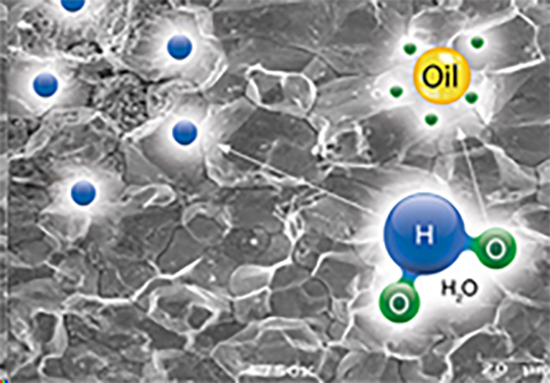

Contamination: The ingress of dirt, moisture and other contaminants into turbine and generator systems accelerates wear, causes blockages and impairs lubricant effectiveness. Insufficient lubrication or contamination can lead to increased vibration, friction, excessive wear and premature failure of bearings, or even catastrophic failure of the system.

Corrosion: The chemical reaction of metal components to environmental factors such as moisture, oxygen, sulfur or chloride can result in rust, pitting or scaling on surfaces, reducing the durability of the parts. Corrosion-resistant materials and contaminant-fighting lubricants can help protect individual components.

Erosion: Blade wear from the impact of solid particles carried by the steam or gas flow can cause cracks, pits or holes on the blades, reducing performance and increasing the risk of failure. Proper filtration and screening of the air and fuel and the use of erosion-resistant materials can help protect the blades.

Fouling: The accumulation of dirt, dust, oil and other contaminants on the blades of the turbine reduces efficiency and output. Fouling can be caused by poor air or fuel quality, inadequate filtration or environmental factors. Regular cleaning and inspection of the blades and high-quality fuels and lubricants can help prevent fouling.

Galling: A lack of lubrication results in friction. As friction builds, so does heat. Without lubrication to separate the components, the parts can touch and bond. This is referred to as galling.

Lubricant Oxidation: Extreme temperature fluctuations in lubricants can lead to the formation of varnish, resulting in filter and strainer plugging and blockages in control valves and heat exchangers. Improper oil management reduces lubricant life and leads to premature equipment failure.

Mechanical: Turbine and generator stators, rotors and bearings are constantly stressed from centrifugal forces and extreme temperatures and pressures, which are amplified by contamination and improper lubrication, leading to reduced efficiency, fatigue and component failure.

Overheating: Increased temperatures are caused by excessive load, friction, cooling-system failures or other operating conditions. Overheating causes thermal expansion and parts deformation, which reduces the efficiency and life of the equipment and can lead to catastrophic failure. Adequate ventilation, cooling, insulation and lubrication can help prevent equipment from overheating.

Vibration: Oscillation due to imbalance of rotating parts, misalignment of shafts or loosening of bolts causes damage to the bearings, seals, couplings and other components. Balancing and alignment, dampers and isolators, along with proper lubrication, can all help prevent vibration.

AMSOIL Industrial: Engineered Solutions for Optimal Power Generation

Power generation lubrication is not “one size fits all.” AMSOIL Industrial formulates specific lubricants that meet the requirements of each individual application and your business objectives. Our products are engineered to withstand high temperatures, pressures, loads and the environmental challenges of power generation facilities by preventing wear, improving efficiency, extending equipment life and reducing maintenance costs and environmental impact.

Expertise. Insight. Solutions.

Our Certified Lubrication Specialists and Application Engineers work alongside you to uncover the issues that are reducing productivity in your power generation facility and provide targeted recommendations so you can boost productivity and save money.

Specialized solutions to help reduce downtime and make production goals may include:

-

Lubricant analysis: Provides timely, accurate and comprehensive fluid analysis to help detect lubricant or equipment issues.

-

Labeling and handling: Special labels help ensure the proper lubricant is being used when topping off a reservoir.

-

Consolidation: A Certified Lubrication Specialist can help you identify ways to consolidate lubricants, saving floor space and decreasing the risk of misapplication.

-

Education: With over 50 years of industry expertise, we gladly pass on our knowledge to you, empowering you with the information you need to implement a successful lubrication program. As you learn more, we hope you’ll no longer view lubricants as consumables and start seeing them as assets.

Contact an AMSOIL Industrial Application Engineer to discuss customized power generation solutions designed to reduce downtime and increase operational efficiency in your power generation facilities.