Electricity is the backbone of modern society, keeping our machines running and our world illuminated. Like any complex system, power generation relies on a delicate balance of equipment working in perfect harmony. Lubrication plays a critical role in maximizing profitability by ensuring efficient performance, extending equipment life and reducing downtime.

The Lubrication Challenge in Power Generation

The continuous operation of power generation equipment creates extreme temperatures, high pressures and constant vibration that can quickly degrade lubricants and lead to equipment failure. Traditional lubrication efforts often reduce efficiency and increase downtime and maintenance costs due to premature equipment failure. Modern lubrication technology offers a solution.

Meeting the Challenge: A Data-Driven Approach

Fortunately, advanced lubrication programs and data-driven insights are now available to address these challenges. Proper lubrication reduces friction to mitigate equipment wear, which helps prevent catastrophic failures and increases efficiency. By implementing a comprehensive lubrication program, power generation companies can:

-

Extend equipment life: High-performance lubricants can withstand extreme conditions, reducing wear and tear on critical components, leading to longer equipment life and lower replacement costs.

-

Increase efficiency: Proper lubrication reduces friction, resulting in lower fuel consumption, increased energy output and improved environmental performance.

-

Reduce downtime: Predictive maintenance supported by oil analysis enables proactive identification and correction of potential problems before they cause equipment failure and downtime.

For example, synthetic lubricants help protect against premature equipment failure by providing excellent thermal and mechanical stability to fight oil breakdown and maintain oil viscosity under high speeds, pressures and temperatures.

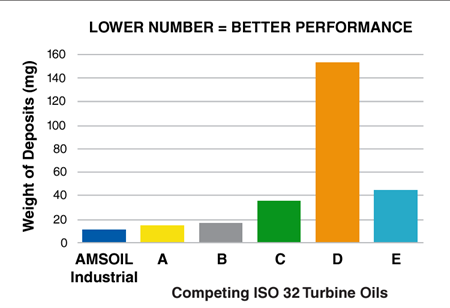

Routine oil analysis provides valuable insights into the health of your equipment and the performance of your lubricants. Analyzing your oil helps identify potential problems early to help you optimize your lubrication program for maximum efficiency and reliability. We tested six leading turbine oils to see which one performs the best.

Thermal Stability

The Lubricant Temperature Aging Test (MAN-LTAT) is a thermal-stability test for turbine oil that includes a visual color assessment between new oil and stressed oil and determines the tendency for deposit formation by measuring the mass of deposits in the stressed oil.

In the visual assessment testing, new oil was poured into an open beaker and maintained at 180ºC for 48 hours. The color assessment between new oil and stressed oil indicates the degree of thermal stress. The darker the oil after testing, the less resistant it is to thermal stress. In this visual assessment of six turbine oils, AMSOIL Industrial Synthetic Gas Turbine Oil changed least in color, indicating superior resistance to thermal stress.

Deposit Formation

The stressed oils were also filtered through a 0.45-micron nitrocellulose paper filter. The resulting deposits (sludge) were weighed and the results of all six oils are shown in the graph at right. A lower amount of deposits indicates better resistance to thermal stress. Of the six oils tested, AMSOIL Industrial Synthetic Gas Turbine Oil had the lowest amount of deposits per volume, indicating better protection against varnish formation.

Getting Started

Lubrication plays an essential role in helping the highly regulated power industry meet the ongoing challenges of optimizing performance while maintaining safety and profitability. A proactive approach to a successful lubrication program involves forging strong partnerships.

AMSOIL Industrial provides proven lubrication solutions with a commitment to quality and reliability that aligns seamlessly with industry demand for uninterrupted operation. Our lubrication experts understand the harsh operational conditions of power generation equipment and partner with you to understand your specific needs and develop solutions that address your unique challenges. Many power generation companies have already experienced the benefits of implementing a comprehensive AMSOIL Industrial lubrication program.

By partnering with AMSOIL Industrial, power generation companies gain access to high-performance lubricants, comprehensive expertise and the continuous support needed to exceed operational goals. AMSOIL Industrial Certified Lubrication Specialists and Application Engineers will help you unlock the benefits of a data-driven lubrication program, including:

-

Improved efficiency and environmental performance

-

Increased productivity and energy output

-

Reduced downtime and maintenance costs

-

Extended equipment life