Problem

Operating hydraulic equipment with monograde hydraulic oil does not allow for additional efficiencies that could be achieved with a synthetic hydraulic oil.

Solution

AMSOIL Industrial engineers conducted a field test on a large blow molding company’s Hesta Graham* HLD700 blow-molding machine to identify potential energy savings when a competitor’s monograde hydraulic oil was replaced with AMSOIL Industrial HELIOS-VR Synthetic Varnish-Resistant Hydraulic Oil. The existing ISO 68 monograde hydraulic oil was drained and refilled according to standard procedure. Baseline energy consumption was recorded for a total production runtime of 278 hours using an AEMC* PEL 103 electric logger installed on the 33.5-hp Leroy Somer* LS180LR-T three-phase motor, running a Voith* Turbo IPV 5-50 101 gear pump. The monograde oil was replaced with AMSOIL Industrial ISO 68 HELIOS-VR Synthetic Varnish-Resistant Hydraulic Oil using the same standardized drain and refill procedure, and electricity consumption was recorded with the same logger for a total production runtime of more than 278 hours.

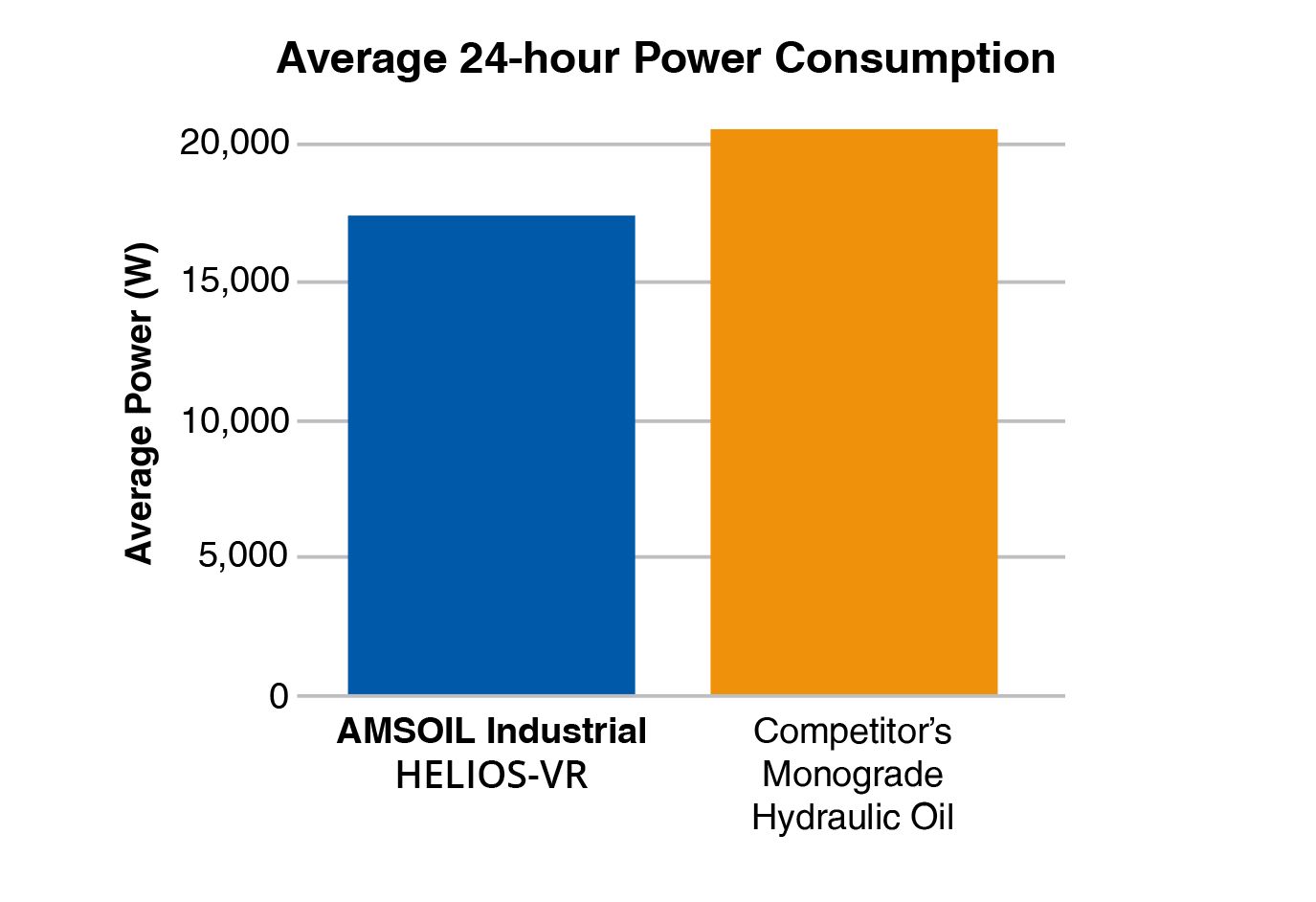

Average power consumption was compared for both oils using continuous 24-hour production runs representative of the entire dataset collected for each oil. All other variables were identical to ensure hydraulic oil was the only differentiating factor for the duration of the trial.

Results: 13.7% Less Energy Used**

Average power consumption over a continuous 24-hour production run for the monograde hydraulic oil was 20,189W. AMSOIL Industrial HELIOS-VR Synthetic Varnish-Resistant Hydraulic Oil used 17,415W, a difference of 2.77kW or 13.7% less energy used.

Savings: $27,360/year**

By switching to AMSOIL Industrial HELIOS-VR Synthetic Varnish-Resistant Hydraulic Oil in more than 20 similar machines running an average of 6,000 hr/yr each, the company could save more than 332,400 kWh and $27,360 in energy costs annually, while simultaneously providing superior equipment protection and reducing maintenance downtime.

Product Benefits

• Resists varnish to improve performance and reliability.

• Extends oil life for decreased maintenance.

• Improves filterability and system cleanliness.

• Maintains viscosity in extreme temperatures, reducing warm-up times, pressure spikes and erratic operation

*All trademarked names are the property of their respective owners and may be registered marks in some countries. No affiliation or endorsement claim,

express or implied, is made by their use.

**Based on one customer’s experience using AMSOIL Industrial ISO 68 HELIOS-VR Synthetic Varnish-Resistant Hydraulic Oil in a Hesta Graham HLD700 blow-molding

machine for two months. Your actual savings will vary depending on energy prices and your current oil, equipment and maintenance practices.